| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Guojin

Model Number : HSMG-10

Certification : ISO

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Supply Ability : 10 sets per month

Delivery Time : 20-30days

Packaging Details : Standard export Carton

Item Name : HSMG Series High Shear Mixer Granulator

Application : Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing

Model type : HSMG-10

Production capacity : 3kg/batch

Granules size : 20-80mesh

Working time : 5-7min

Container volume : 10L

Mixing power : 2.2kw

Cutting power : 1.1kw

Mixing speed : 30-600r/min

Cutting speed : 300-3000r/min

Consumption of compressed air : 0.1Mpa

Weight : 300kg

Overall dimension : 1250x550x1160mm

HSMG Series High Shear Mixer Granulator

HSMG high speed mixer granulator is a high efficiency equipment that can mix different powder materials and granulate granule in one procedure. It is widely used for pharmaceutical industry, foodstuff industry and chemical industry, etc.

1. The High speed HSMG series wet type mixing granulator adopts a practical horizontal cylinder structure.

2. The driving shaft is euipped with inflatable seal. While washing, the air can be replaces by water.

3. Fluidized granulating processed is used and the final granules are quite round with high fluidity.

4. Compared with traditional technique, this type of machine can reduce 25% of adhesive and also shorten the drying time.

5. For each batch of material, with 2 minutes dry mixing and 1-4 minutes granulating, the efficiency is 4-5 times higher than that of traditional technique.

6. Dry mixing, wet mixing and granulating are finished inside the same sealed container, which is in conformity with the requirement of GMP.

1. The whole process consists of two programs including mixing and granulating.

2. Powder metrical can be charged into the material pan from the conical hopper and continue to rotate in the container under the action of mixing blade once the hoper is closed. In tahe meanwhile, all materials grow up the shapea of liquid bridge under continuous effects of conical wall. Under the action of extrusion, friction as well as crumb by blade and conical tank wall, all material is gradually turn for loosen. At last,while opening the hoper outlet, waterish particles are pushed off under the centrifugal effects of blade.

3. These soft particles are formed not dependent on forced extrusion effects, more exactly; these small and uniform particles are mainly formed after continuous cutting under the similar-liquid state. In all, this machine can realize the mutual transformation between different materials.

Technical Parameters

| Model | 7/2.5 | 10 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 600 |

| Productive capacity(kg/batch) | 0.3-1 | 3 | 15 | 35 | 50 | 60 | 80 | 100 | 135 | 200 |

| Granules size(mesh) | 20-80 | |||||||||

| Working time(min) | 5-7 | |||||||||

| Container volume(L) | 7/2.2 | 10 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 600 |

| Mixing power(kw) | 0.75 | 2.2 | 4/5.5 | 6.5/8 | 6.5/8 | 11/14 | 11/14 | 13/16 | 18.5/22 | 22/28 |

| Cutting power(kw) | 0.75 | 1.1 | 1.3/1.8 | 2.4/3 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 | 9/11 |

| Mixing speed(r/min) | 30-1000 | 30-600 | 200/400 | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 | 80/120 |

| Cutting speed(r/min) | 300-3000 | 1500/3000 | ||||||||

| Pressure of compressed air(Mpa) | 0.3-0.6 | |||||||||

| Consumption of compressed air(M3/min) | No | 0.1 | 0.11 | 0.13 | 0.2 | 0.25 | 0.25 | 0.3 | 0.4 | 0.4 |

| Weight(kg) | 150 | 300 | 400 | 800 | 900 | 1200 | 1500 | 1550 | 1650 | 1800 |

| Overall dimension(mm) | 800*450 *900 | 1250*550 *1160 | 1730*750 *1610 | 1950*750 *1810 | 1950*750 *1810 | 2210*880 *2000 | 2210*880 *2000 | 2310*1050 *2000 | 2485*1050 *2050 | 2585*1400 *2100 |

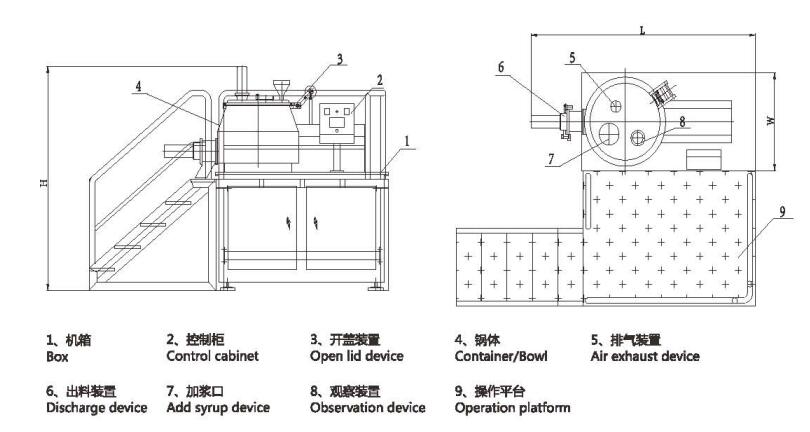

Chart of overall dimensions

Product Show

electrical, steam, natural gas or other

|

|

10L 80 Mesh High Shear Mixer Granulator GMP Standard Images |